In the world of modern manufacturing and metal processing, precision and efficiency are critical. Among the many components that make this possible, the 90 Laser Chuck stands out as one of the most essential tools in laser cutting machinery. Built for stability, strength, and accuracy, this advanced chuck system ensures that pipes and profiles are held firmly in place during high-speed cutting operations. Whether for large-scale industrial setups or specialized fabrication shops, the 90 Laser Chuck plays a pivotal role in improving cutting performance, enhancing safety, and reducing setup time.

Understanding the 90 Laser Chuck

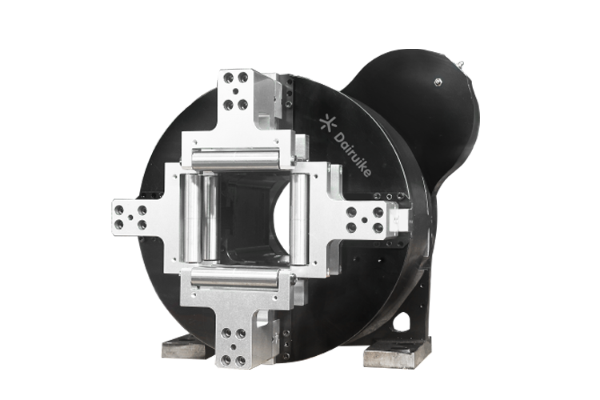

The 90 Laser Chuck is a highly specialized work-holding device designed to clamp and rotate pipes, tubes, and other materials during laser cutting. Its name refers to its 90mm diameter size specification, making it ideal for a wide range of pipe-cutting applications. What sets this chuck apart is its innovative pneumatic system, compact design, and high-precision clamping capability that allows laser cutting machines to operate with minimal vibration and exceptional accuracy.

This component has become a standard in many fiber laser pipe cutting machines due to its efficient structure and stable performance. The chuck operates pneumatically—meaning it uses air pressure to clamp materials—offering fast, repeatable, and reliable performance with minimal manual intervention.

Hollow Pneumatic Chuck (Front Chuck): Flexibility Meets Speed

A perfect complement to the 90 Laser Chuck is the Hollow Pneumatic Chuck (Front Chuck). This front chuck design provides a hollow passage through which pipes can pass easily, making it highly suitable for long workpieces. Its pneumatic operation enables automatic clamping, which drastically reduces the time needed to load and unload materials.

The hollow design also reduces the total weight, allowing for faster rotational speeds and smoother motion. When integrated into laser cutting machines, it ensures consistent clamping pressure and prevents pipe deformation—an important factor in maintaining cutting precision and product quality.

Hollow Pneumatic Chuck (Rear Chuck): Ensuring Perfect Synchronization

The Hollow Pneumatic Chuck (Rear Chuck) works in tandem with the front chuck to ensure seamless pipe rotation and alignment. It provides synchronized movement with the front chuck, allowing for longer and more stable workpieces to be processed efficiently.

Its pneumatic control system ensures that clamping and unclamping actions are both quick and consistent. This synchronization helps prevent vibration during high-speed laser cutting, ensuring smoother edges and more precise cutting results.

Solid Pneumatic Chuck (Rear Chuck): Strength and Durability Combined

For heavier materials that require extra support and stability, the Solid Pneumatic Chuck (Rear Chuck) is a powerful solution. Unlike hollow chucks, the solid design provides maximum rigidity and eliminates potential bending or twisting of the material.

It’s perfect for industrial applications involving dense or thick-walled tubes. The solid pneumatic chuck’s reliability ensures that even under high clamping forces, the alignment remains consistent, which enhances both cutting accuracy and equipment longevity.

Moving Beyond: The 120 Laser Chuck for Heavy-Duty Applications

As manufacturing demands increase, so does the need for larger and more powerful equipment. The 120 Laser Chuck is designed for heavier-duty laser cutting machines. With a larger diameter and stronger pneumatic force, it’s ideal for handling bigger pipes and complex industrial tasks.

This chuck maintains the same precision and quick clamping performance as the 90 Laser Chuck but on a larger scale. It’s an excellent upgrade for workshops looking to expand their capabilities in processing thicker and longer materials.

Pneumatic Power Chuck (Front Chuck): Efficiency in Every Rotation

Another reliable option in the Dairuike lineup is the Pneumatic Power Chuck (Front Chuck). This model focuses on providing superior clamping power with fast response times. Designed with automation in mind, it integrates seamlessly into CNC and laser cutting systems.

The pneumatic mechanism ensures that the chuck operates consistently even after thousands of cycles. This makes it especially useful for continuous production lines where uptime and reliability are crucial.

Laser Chuck (Rear Chuck): Stability That Supports Precision

Behind every precise front chuck is a dependable rear chuck. The Laser Chuck (Rear Chuck) ensures that materials are held securely from the back, preventing any shift during high-speed rotation. It’s designed for perfect alignment and minimal runout, which is key for achieving flawless laser cuts.

By maintaining consistent clamping force, this rear chuck helps reduce machine wear and supports long-term operational accuracy, even under continuous workloads.

Laser Rotary Chuck (Front Chuck): Innovation in Pipe Cutting

The Laser Rotary Chuck (Front Chuck) introduces enhanced flexibility to laser cutting systems. With its rotary function, it allows precise control over pipe rotation, enabling complex cutting patterns such as angles, holes, and custom profiles.

This chuck is ideal for applications where versatility is needed—such as in architectural, automotive, and aerospace manufacturing. Its advanced design ensures high concentricity and stable rotation, allowing operators to achieve intricate designs effortlessly.

160 Laser Chuck: Power for Industrial-Scale Operations

When it comes to handling extra-large pipes, the 160 Laser Chuck takes performance to another level. Built for heavy-duty industrial cutting, it can accommodate large-diameter materials with ease.

With its robust pneumatic system and superior load-bearing capacity, this model is suitable for factories involved in heavy machinery, shipbuilding, and energy equipment manufacturing. Despite its size, the 160 Laser Chuck maintains excellent clamping accuracy and smooth rotation.

Laser Pipe Cutting Chuck (Front Chuck): Optimized for Precision Cutting

Finally, the Laser Pipe Cutting Chuck (Front Chuck) represents the evolution of laser chuck technology. Specifically designed for precision pipe cutting, this chuck offers automatic centering, high-speed operation, and remarkable stability.

Its design supports different material shapes—round, square, and rectangular pipes—making it one of the most versatile tools for laser cutting systems. When paired with a laser cutting machine, it significantly improves production efficiency and cutting precision.

Why Choose Dairuike Laser Chucks?

Dairuike has earned its reputation as a global leader in producing laser chucks for various industrial applications. Each product—from the 90 Laser Chuck to the 160 Laser Chuck—is engineered for performance, reliability, and innovation.

Their pneumatic chucks deliver advantages such as:

- High clamping accuracy to ensure consistent cutting quality

- Automatic control systems for faster operation

- Durable materials and construction that extend service life

- Compatibility with a wide range of laser cutting machines

- Custom options tailored to specific industry needs

With Dairuike’s expertise and commitment to technological advancement, manufacturers can achieve smoother operations, lower maintenance costs, and improved productivity.

Conclusion

The 90 Laser Chuck and its complementary models from Dairuike form the backbone of modern laser cutting machinery. From compact pneumatic chucks to large-scale rotary systems, each component is meticulously designed to provide unmatched precision, efficiency, and durability.

Whether you’re upgrading your cutting system or designing a new production line, investing in high-quality chucks like the 90 Laser Chuck ensures superior performance and long-term reliability in every cut.